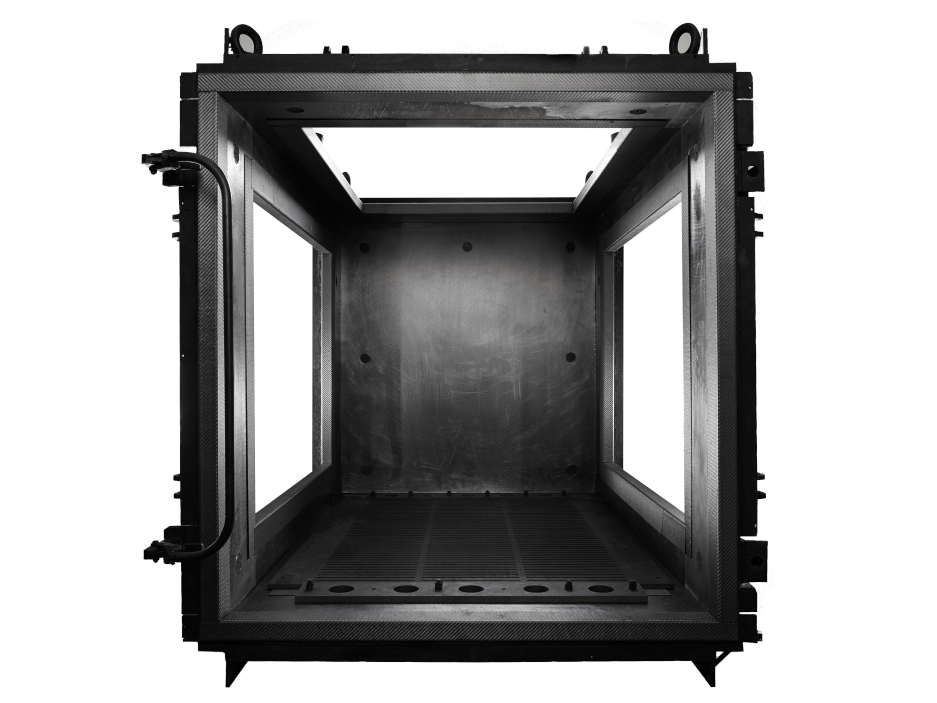

Heating chamber linings and repairs

Reliable, Durable, Efficient: Maximum performance for your vacuum, inert-gas and sintering furnaces.

Graphite Materials helps you to get the most out of your vacuum, inert gas and sintering furnaces. We support you with our experience and expertise. From technical support and the development of graphite and CFC heating systems to professional heating chamber lining and repair.

Our heating-chamber services at a glance:

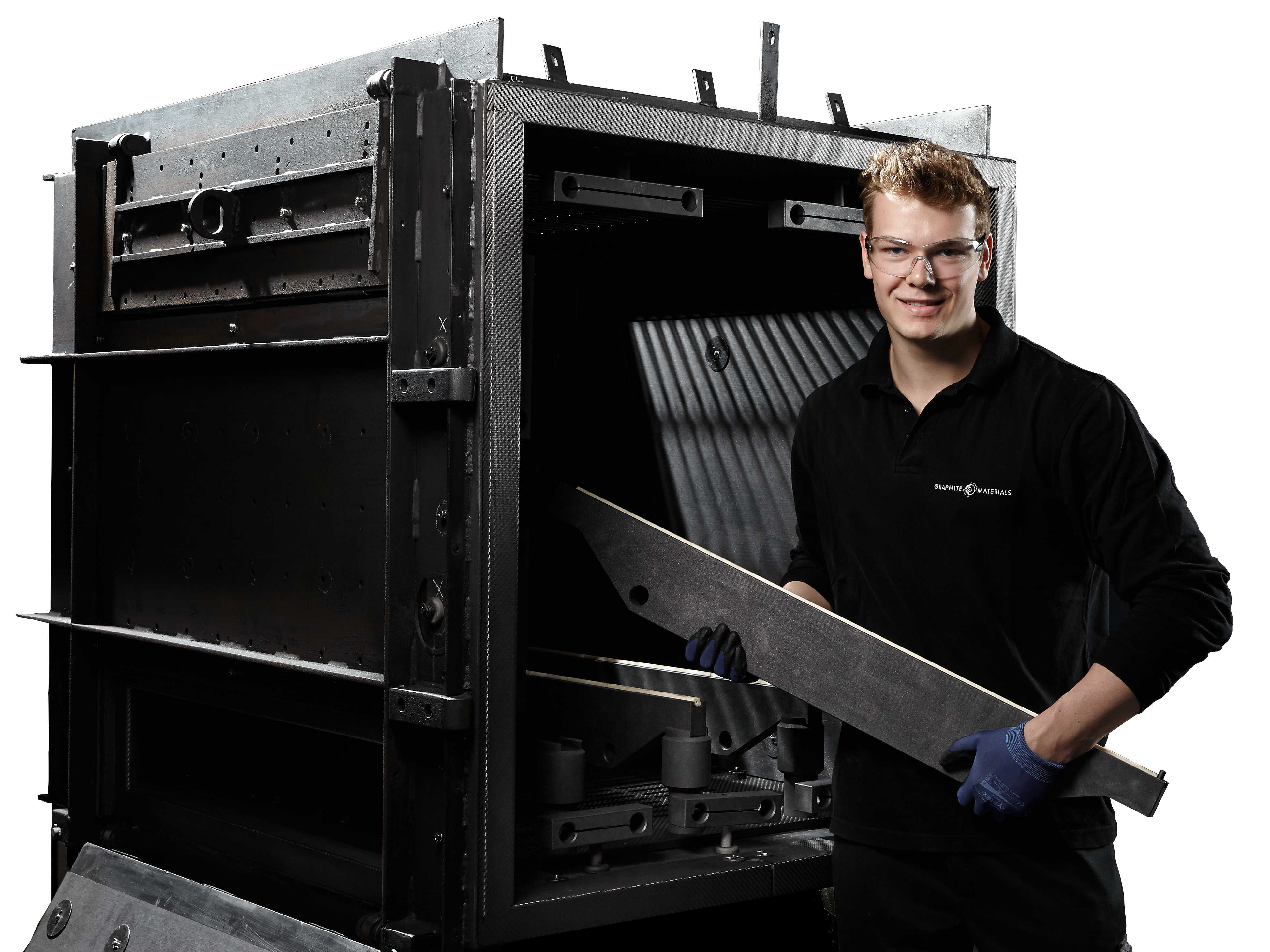

Professional servicing for reliable furnaces

Your industrial furnaces work with maximum efficiency, day after day. This takes its toll: Insulation wears out, heater elements break, steel cages become distorted. Often just when your customer is in urgent need of the product. Don’t lose any time!

Learn more...

Our maintenance services:

- Collection/delivery of the heating chamber

- Dismantling of the old insulation

- Disposal of the old insulation and other defective parts

- Cleaning of the heating chamber

- Repairs to the cage and add-on parts (adjustment, welding, etc.)

- Reconstruction of the heating chamber lining

- Application of surface protection (CFC, graphite foil, graphite coating)

- Installation of edge protection (U-profiles made of CFC)

- Replacement of worn parts (ceramics, molybdenum, etc.)

- Assembly of various add-on parts (current bridges, heating rods, connector pins, batch carriers, etc.)

- Mounting of third-party components

- Adjustment of door and cooling flaps

- Partial disaster recovery

close

Spare parts service: Maximum quality, quick delivery

Short waiting times, no delivery bottlenecks: Graphite Materials replaces

defective parts in your industrial furnace within 24 hours. Our employees manufacture each spare part in top quality to meet your individual requirements.

Learn more...

In the manufacture and technical design of spare parts, we specialize in:

- Heating systems (current bridges, heating rods, connector pins, etc.)

- Batch carriers and posts

- Diffusers and gas-deflecting plates

- CFC fans

- Hard-felt, soft-felt and CFC plates

- Wear parts (ceramic, molybdenum, etc.)

close

Optimization and engineering for excellent

manufacture

With Graphite Materials, you increase the service life and energy efficiency of your industrial furnace. You cut operating costs in the long-term and reduce the risk of production losses and harmful emissions. Important influencing factors include the insulation of the heating chamber, as well as the design of the heating system.

Read more...

Our optimization and engineering services:

- Technical consultation for carbon-fiber furnace insulation (focusing on: energy efficiency and service life)

- Assessment of reactions in production processes between carbon/graphite and other materials

- Design and production of graphite and CFC heating systems in accordance with mechanical and thermal requirements

- FEM simulation and calculation for mechanical and thermal load cases

close