Production

Precision at the highest level

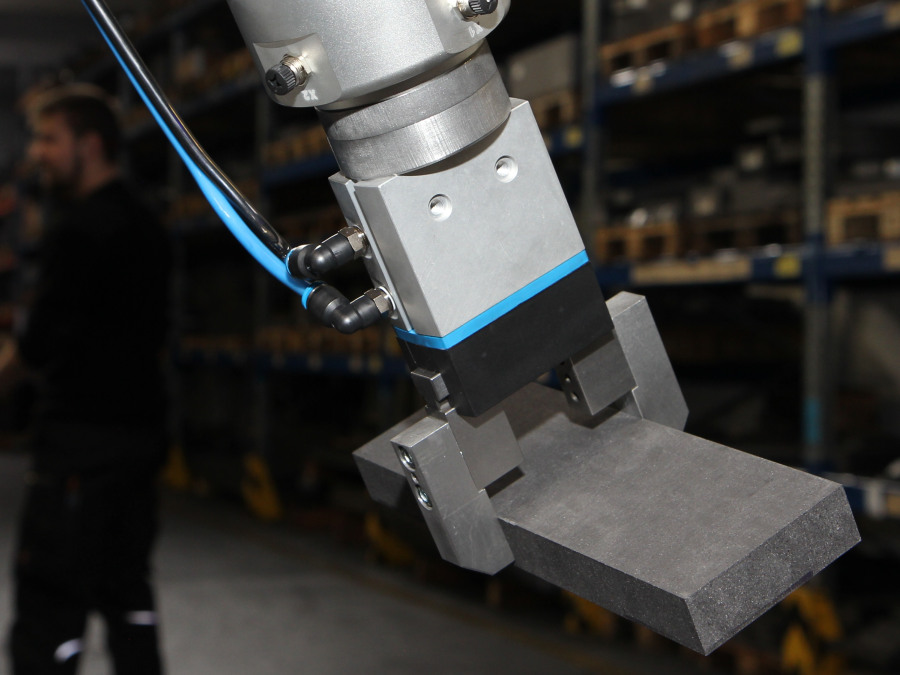

Graphite Materials manufactures over an area of more than 2,500 square meters. With state-of-the-art machinery, we produce semi-finished formats made of graphite, CFC and carbon-fiber felt. These include blocks, billets and plates. Precise mechanical and manual manufacturing processes ensure components of the highest quality – regardless of whether an individual part or series production.

We offer the following services:

CNC milling

CNC turning

Water-jet machining

Sawing

Grinding

robotics

Your contact person:

Do you have questions about our production? Then Mr. Kirchner is your contact.

Adrian Kirchner

Phone: +49 911 999 01 03-42

Fax: +49 911 999 01 03-50