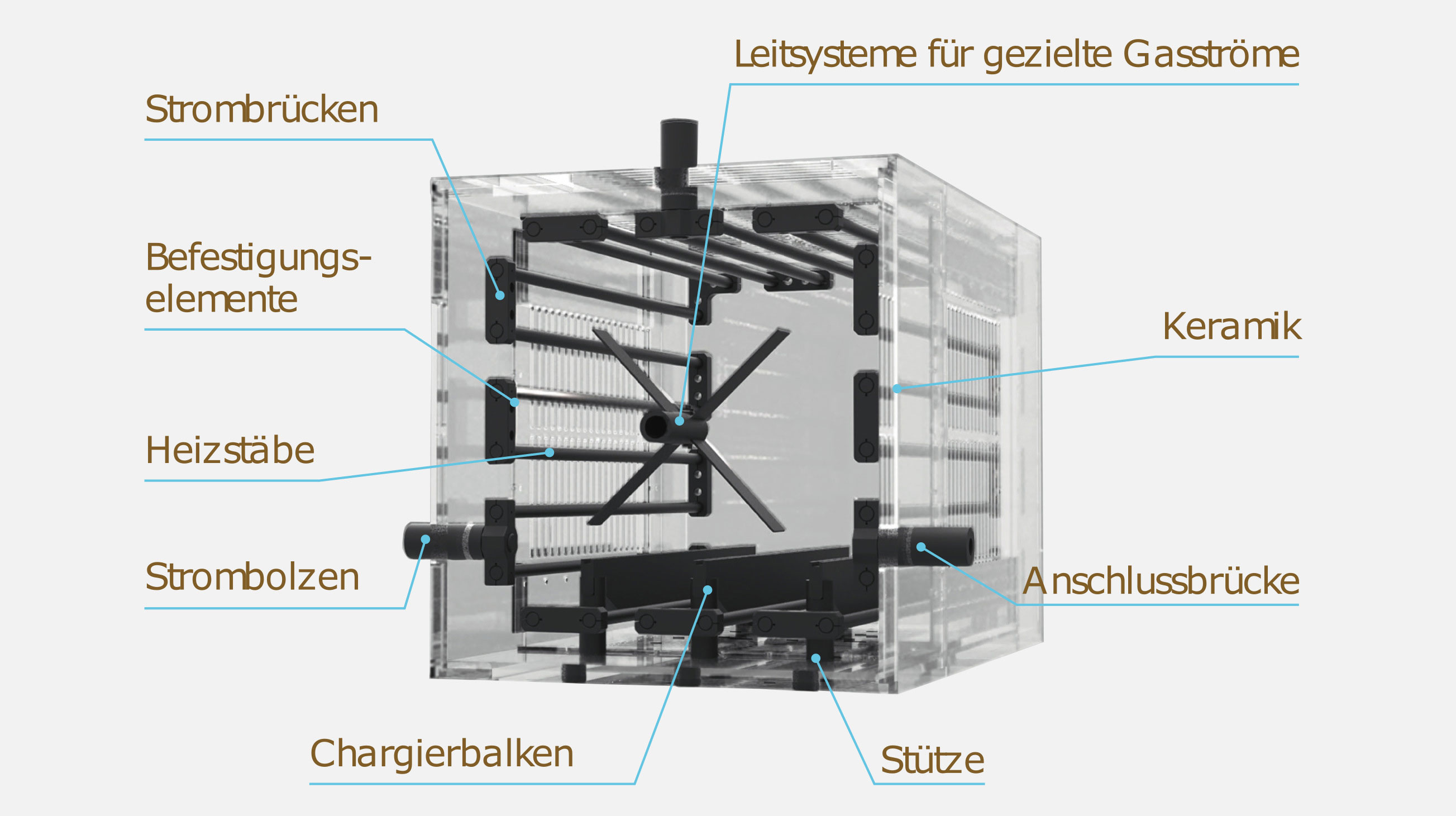

Furnace components

Customized, Tried and tested, Always available: Graphite components for your furnaces.

You can rely on furnace components from Graphite Materials for your high-temperature applications. We manufacture all components you need for the smooth and effective operation of your heat-treatment furnaces. Our graphite components are used, for example, in furnaces for the manufacture of permanent magnets, hard metals and silicon ceramics. They withstand temperatures between 900 and 2.400 °C. Our premium components are also used in heat-treatment systems, vacuum units, crystal-growing systems and soldering furnaces.

Read more...

Our recipe for quality? People, materials, machinery

The performance of your furnaces largely depends on the quality of the materials used in their components. Graphite Materials scores highly here with its experience and specialist knowledge. Our materials engineering department searches extensive databases containing reliable measurement values for the right material. The suitable material is then put through its paces by experienced employees in practical applications. We only use materials that have fully convinced our pecialists. During manufacture, Graphite Materials adapts to your individual requirements. You benefit from our many years of experience and our practical specialist knowledge. These success factors are supplemented by state-of-the-art machinery that is specially adapted for our product portfolio. You receive customized components for high-performance furnaces.

So much more than the sum of its parts. With Graphite Materials you keep your production running.

Flexible manufacture and rapid assistance

Graphite Materials manufactures furnace components in single part and series production. We also keep machine capacities in reserve to be able to provide rapid assistance and hold spare parts in stock. In this way, Graphite Materials helps you keep your production up and running.

close

Graphite Materials manufactures the following components for your furnaces:

Current bridges

Current bridges position and connect the individual heater elements in the heating chamber and then conduct the current to them.

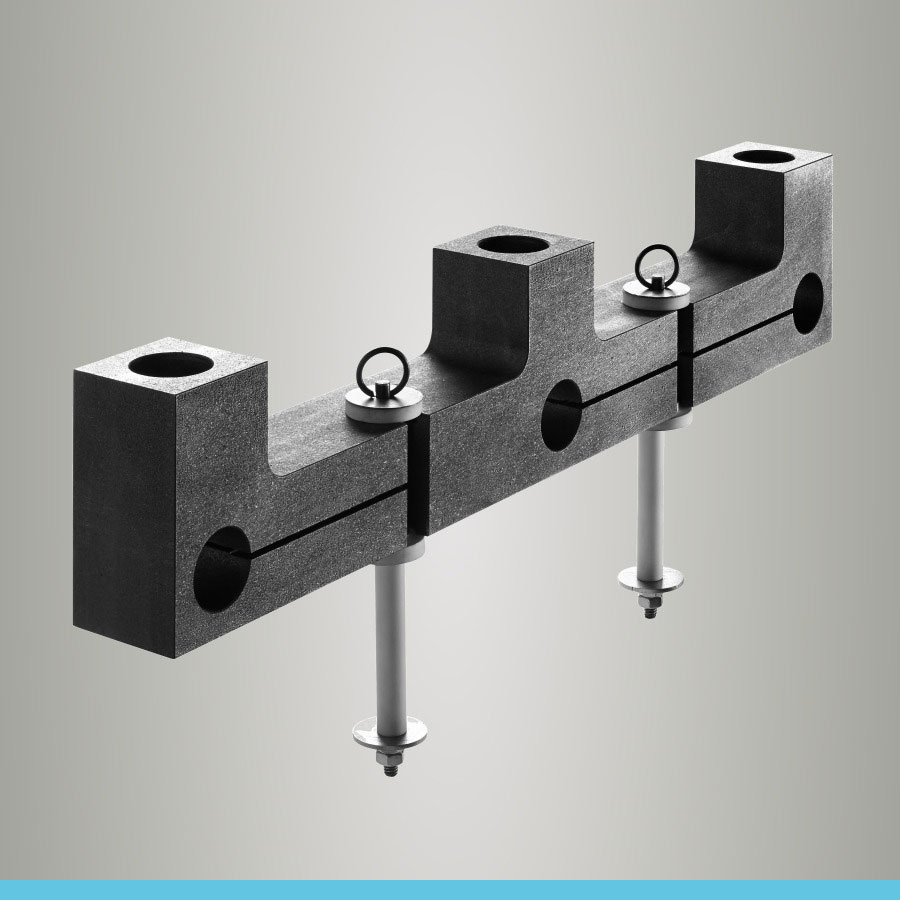

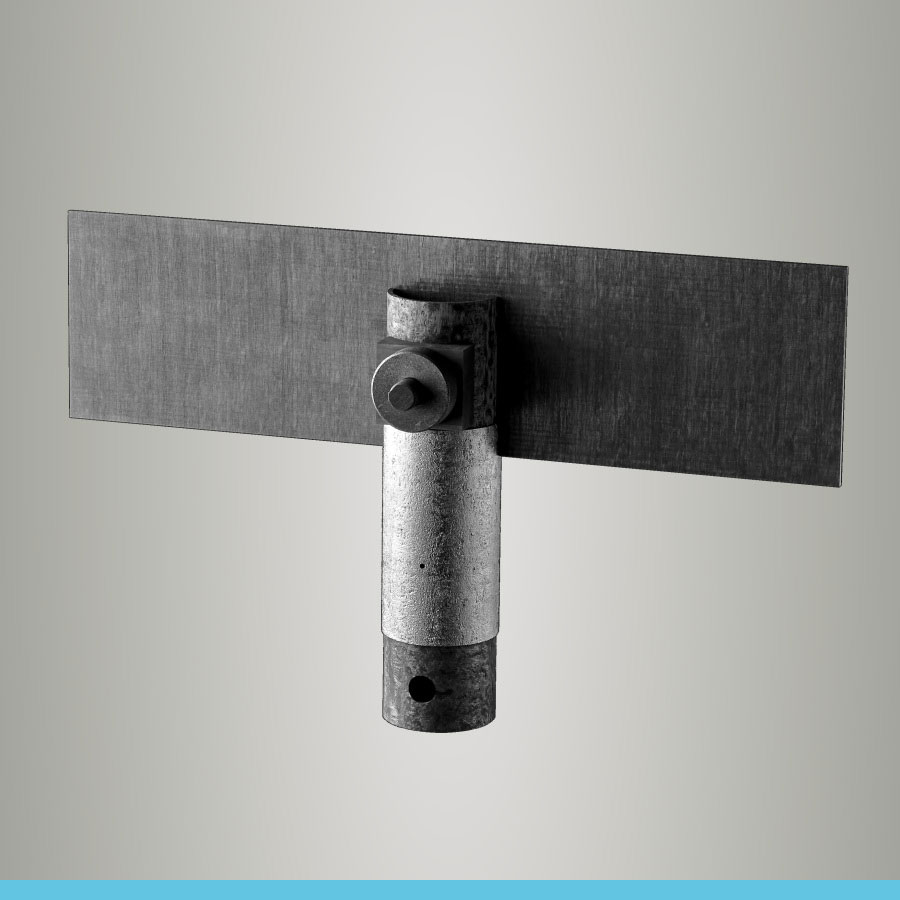

Assembling bolts

Assembling bolts are the interface to the external system. They conduct electricity from the transformer to the heating chamber.

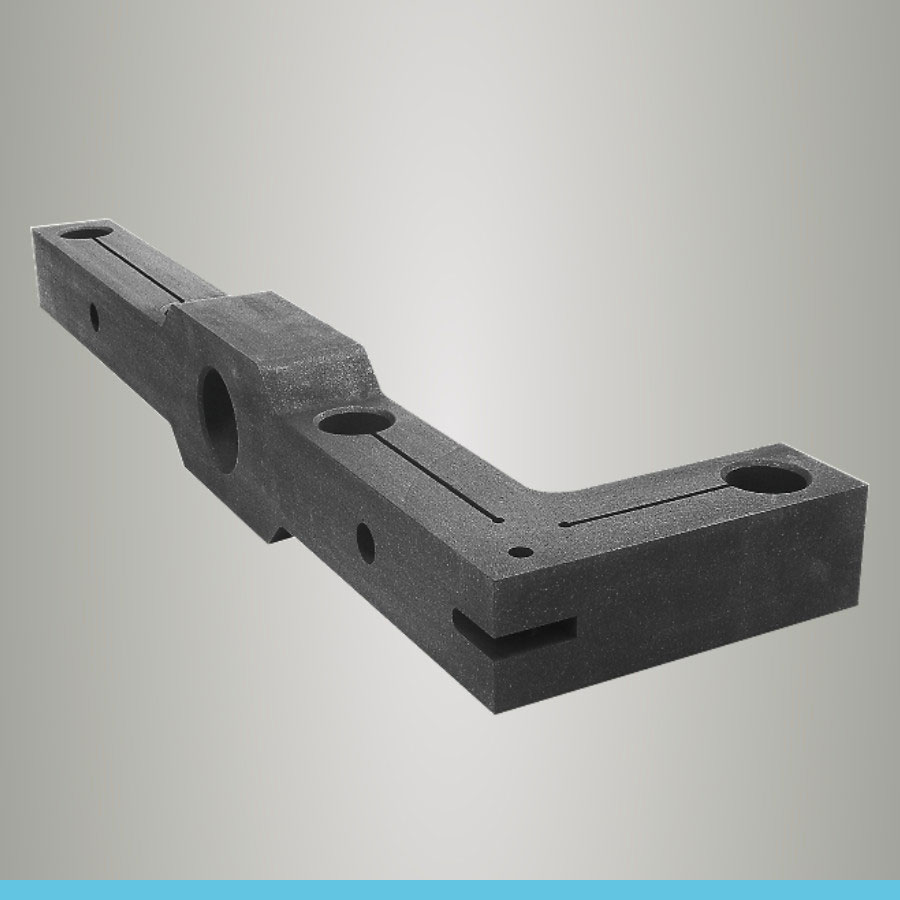

Graphite beams/posts

Like a bridge, graphite beams are supported

by posts. This enables heating elements to also be installed below the product batch.

Heating elements

Electricity flows through the heating elements. The resulting resistance causes them to glow and generate heat

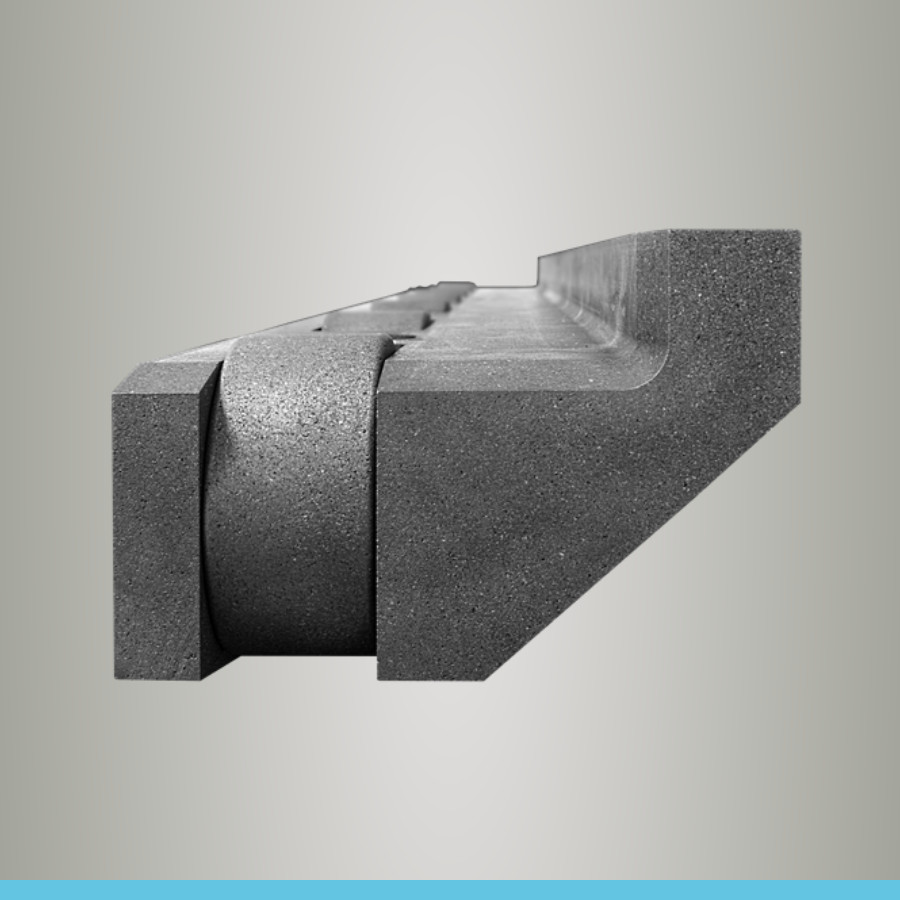

Roller conveyors

The batch is pushed into the heating chamber on a roller conveyor.

Connection bridges

Connection bridges are current bridges to which additional assembling bolts can be connected.

Fastening elements

Fastening elements include molybdenum bolts to attach current bridges, as well as

Erfahren Sie mehr...

Zuklappen

Ceramics

Ceramics insulate current bridges from the steel cage of the furnace.

Control systems for directed gas flows:

With gas quenching, flow-optimized control systems, such as CFC diffusers and CFC fans, direct the cooling flow onto the batch.

Read more…