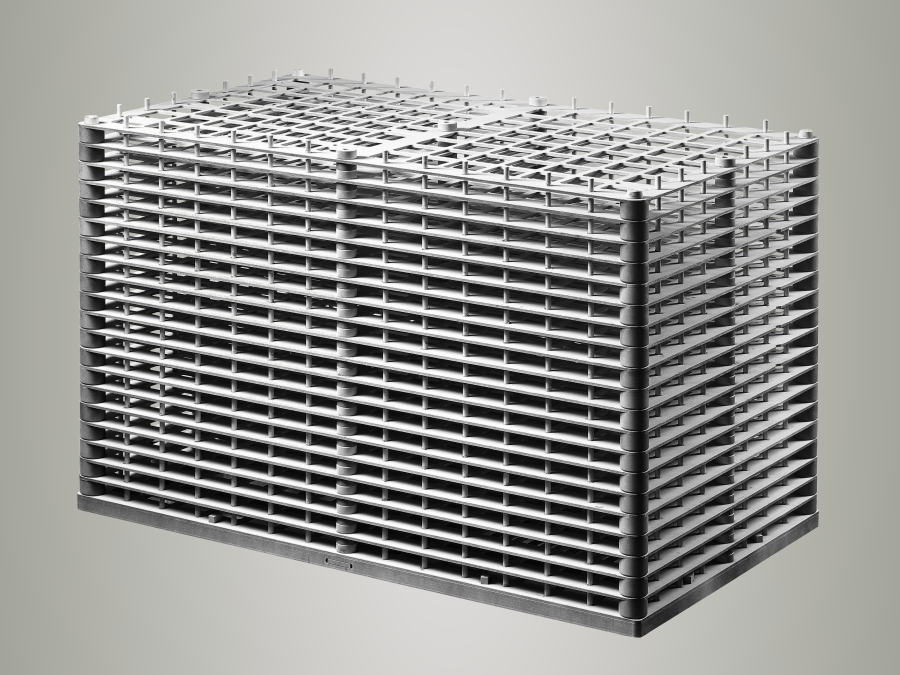

CFC fixtures

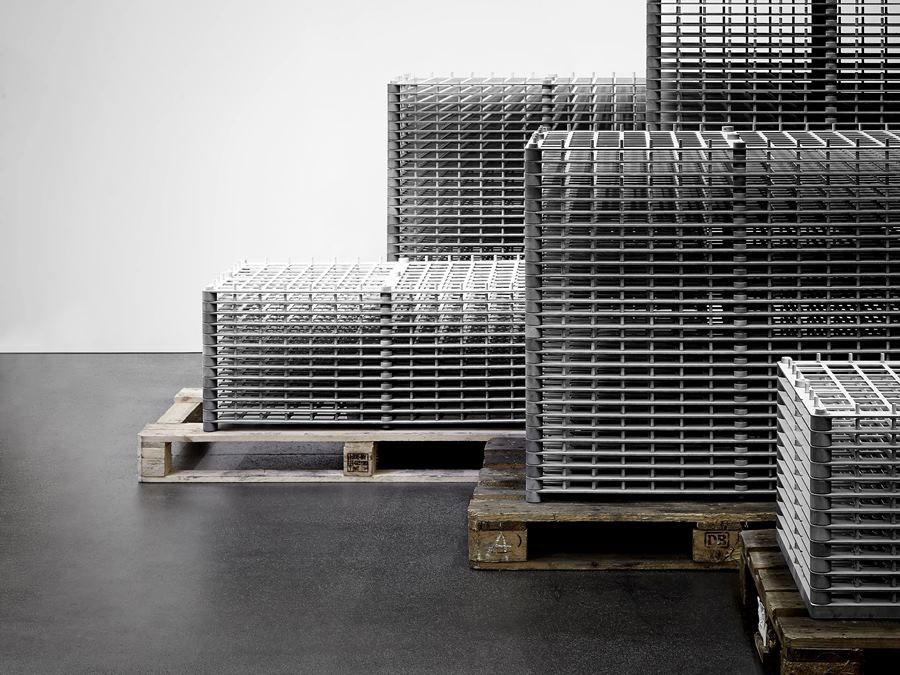

Lightweight, stable, durable: Fixtures also for extreme conditions.

CFC fixtures by Graphite Materials withstand heat of up to 1,300 °C, tremendous temperature fluctuations and a high weight load and still stay “in shape”. This makes them the ideal workpiece fixture for use in heat treatment, for example, when hardening metallic components.

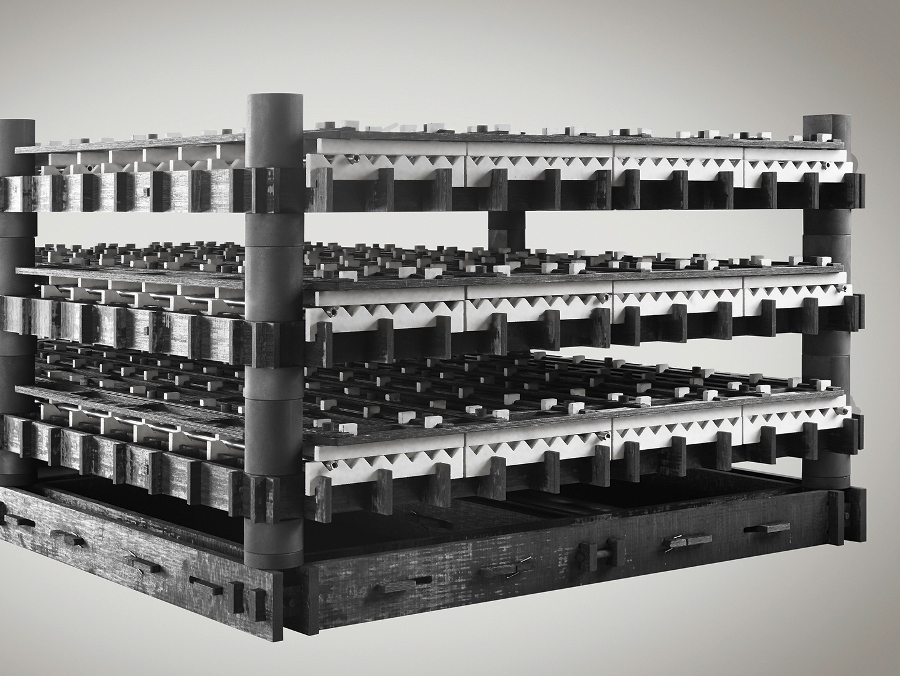

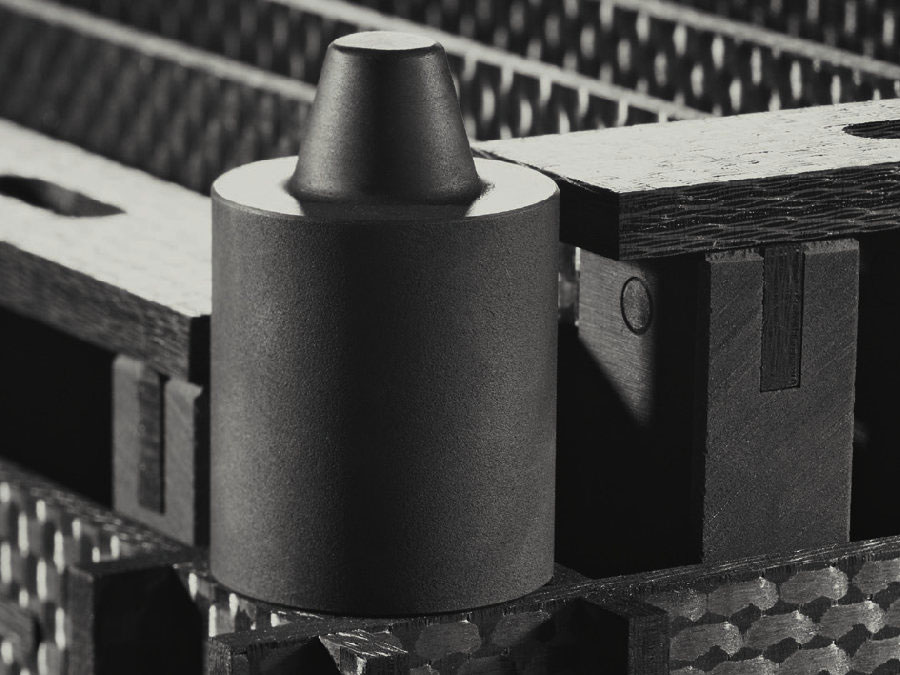

As tough as it comes: CFC

The material used is CFC (carbon fiber carbon composite) and was first used in space flight. In the last 15 years, thanks to its outstanding material properties (dimensionally stable, robust, durable, lightweight), it has become firmly established in heat treatment.

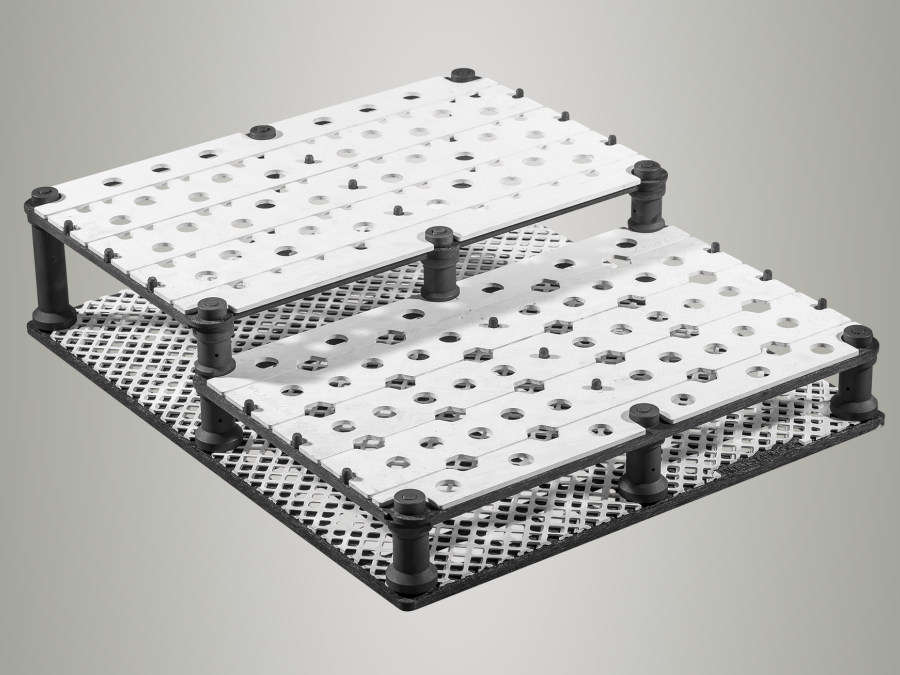

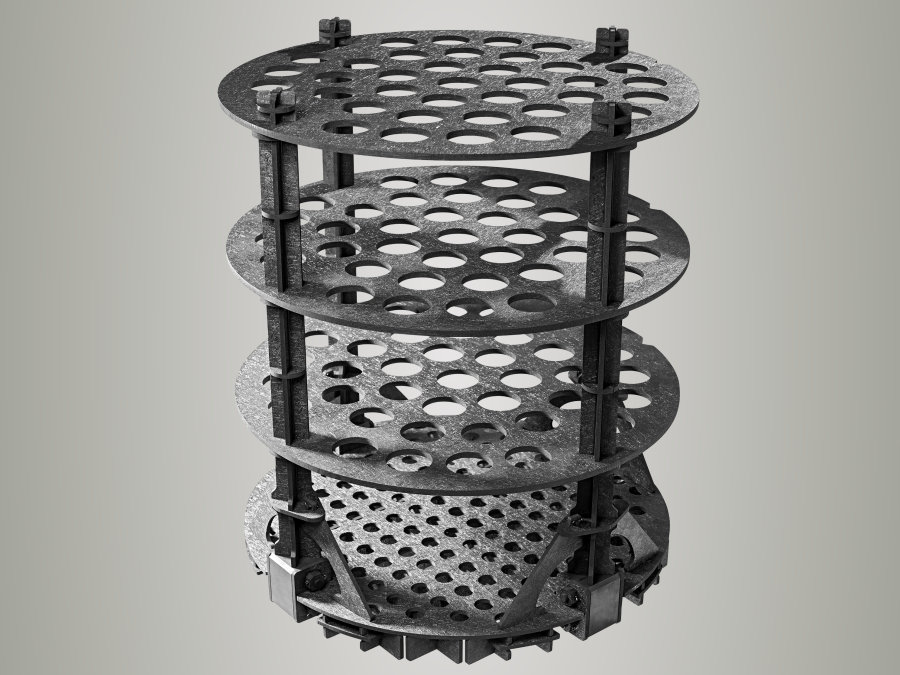

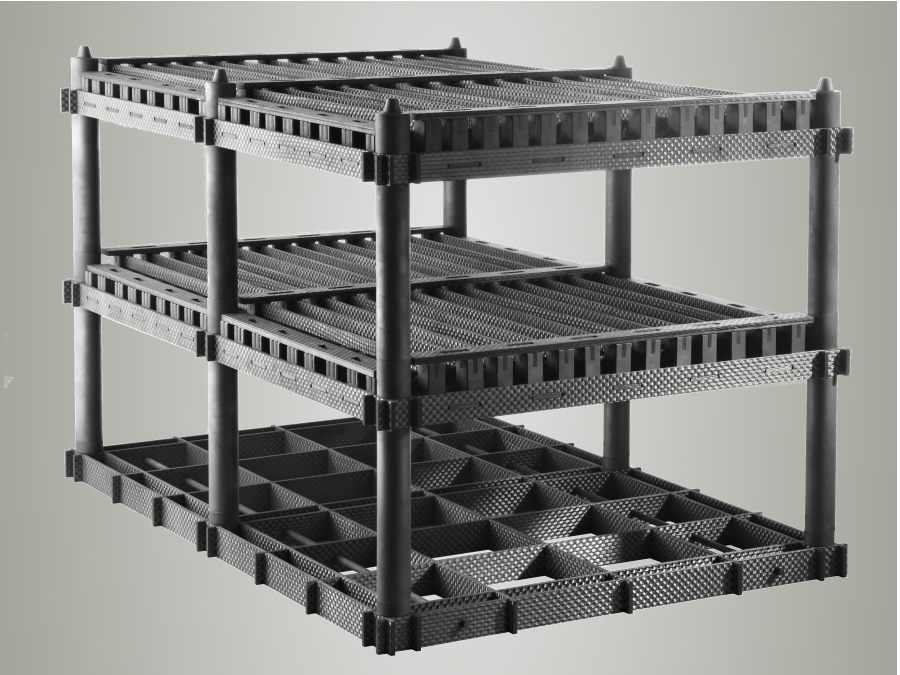

Customized to your needs

Graphite Materials offers CFC fixtures (also known as CFC racks) for numerous application areas that are constantly extended thanks to modern design programs. For example, heavy-duty racks for forming tools with a weight of up to five tons. For particularly hot applications, Graphite Materials relies on its innovative DuComGrid, combining two or more different materials for your carrier system. Operating temperatures of more than 1,300 °C are possible.

Five times lighter than steel fixtures – and yet much stronger. Carbon fiber materials even increase in strength with a rise in temperature.

Whilst steel distorts or deforms at high temperatures, CFC fixtures retain their

shape. This makes them predictable and the components placed on them are protected against unwanted changes. In addition, CFC carrier systems are resistant to the effects of chemicals and extremely durable.

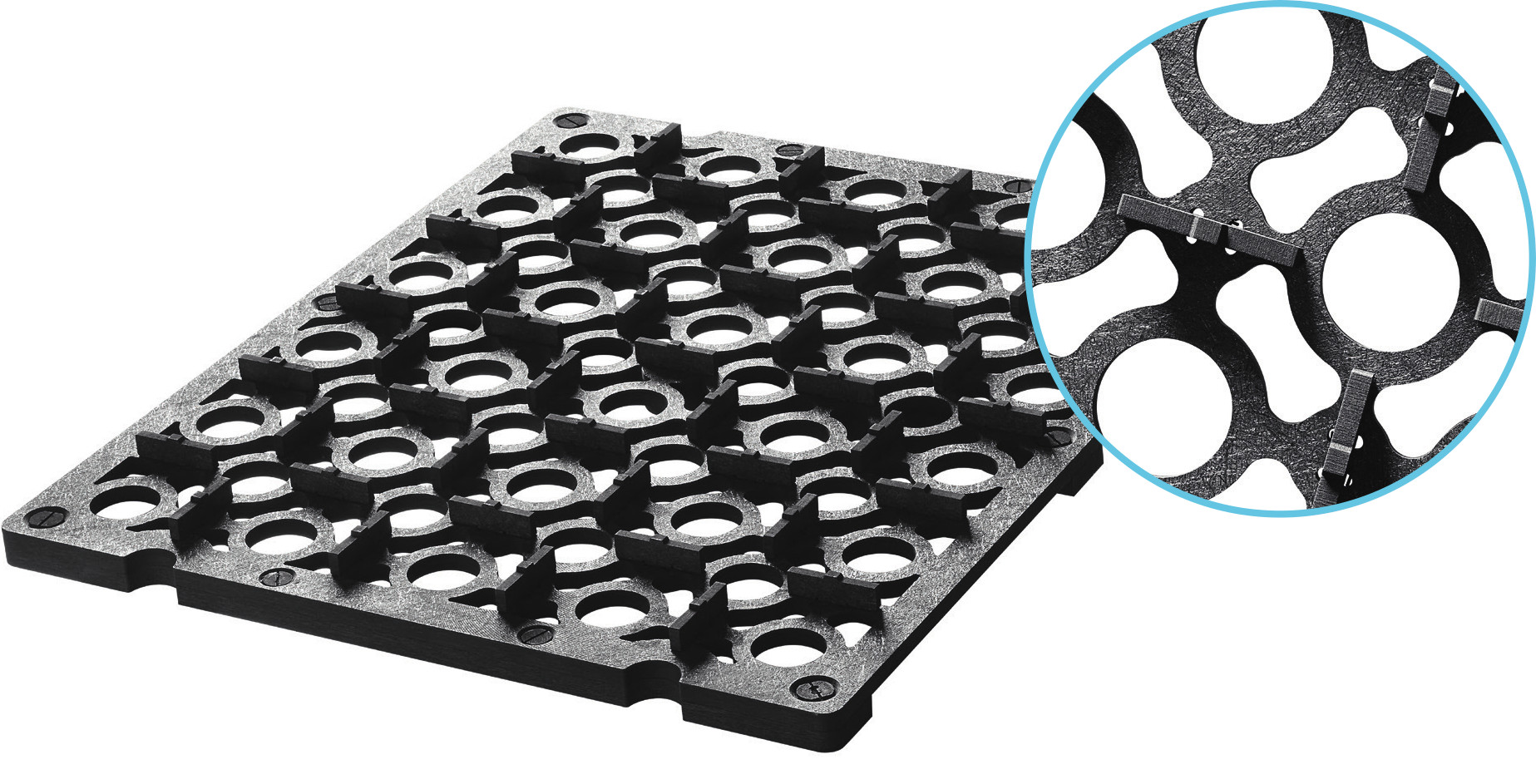

Coding and individualization

Smart fixtures for smart users: Individual coding of our CFC fixtures for process control and maintenance ensures maximum process safety, plannable downtimes and clear identification.