Electrodes

Graphite Materials’ insight into the processes leading to the optimum functionality of a component is also evident in the field of graphite electrodes for electric arc furnaces (EAF) and ladle furnaces (LF for secondary metallurgy). Based on more than 20 years of practical knowledge, the company has developed its own quality system for manufacturing optimum electrode connections.

A piece of Graphite Materials is in almost every industry.

Automotive

Aviation

Powder metal and ceramics

Furnace construction

Heat treatment

CVD coating

Services

Current

Fundraising campaign for the “Wünschewagen”

How collecting deposits turned into something great: Over the past few weeks, our employees from production have collected a [...]

Graphite Materials at the Heat Treat 2023

From 17 to 19 October, our colleagues Roland Weeske and Bastian Schott were exhibitors at the Heat Treat 2023 [...]

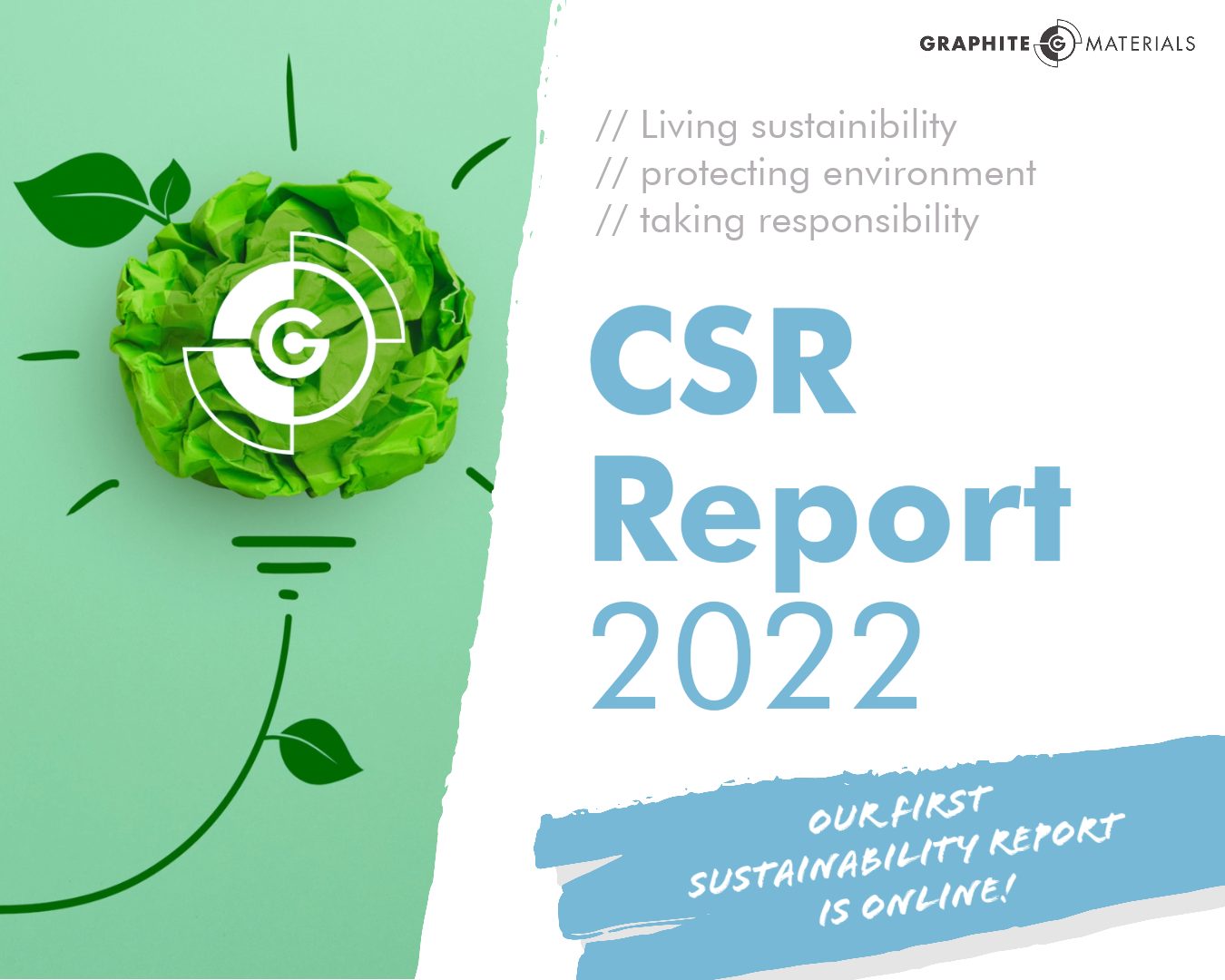

The CSR Report 2022 is here!

Our CSR Report 2022 is online! Living sustainability, protecting the environment and taking responsibility: With our first sustainability report, [...]